What are you looking for?

Search

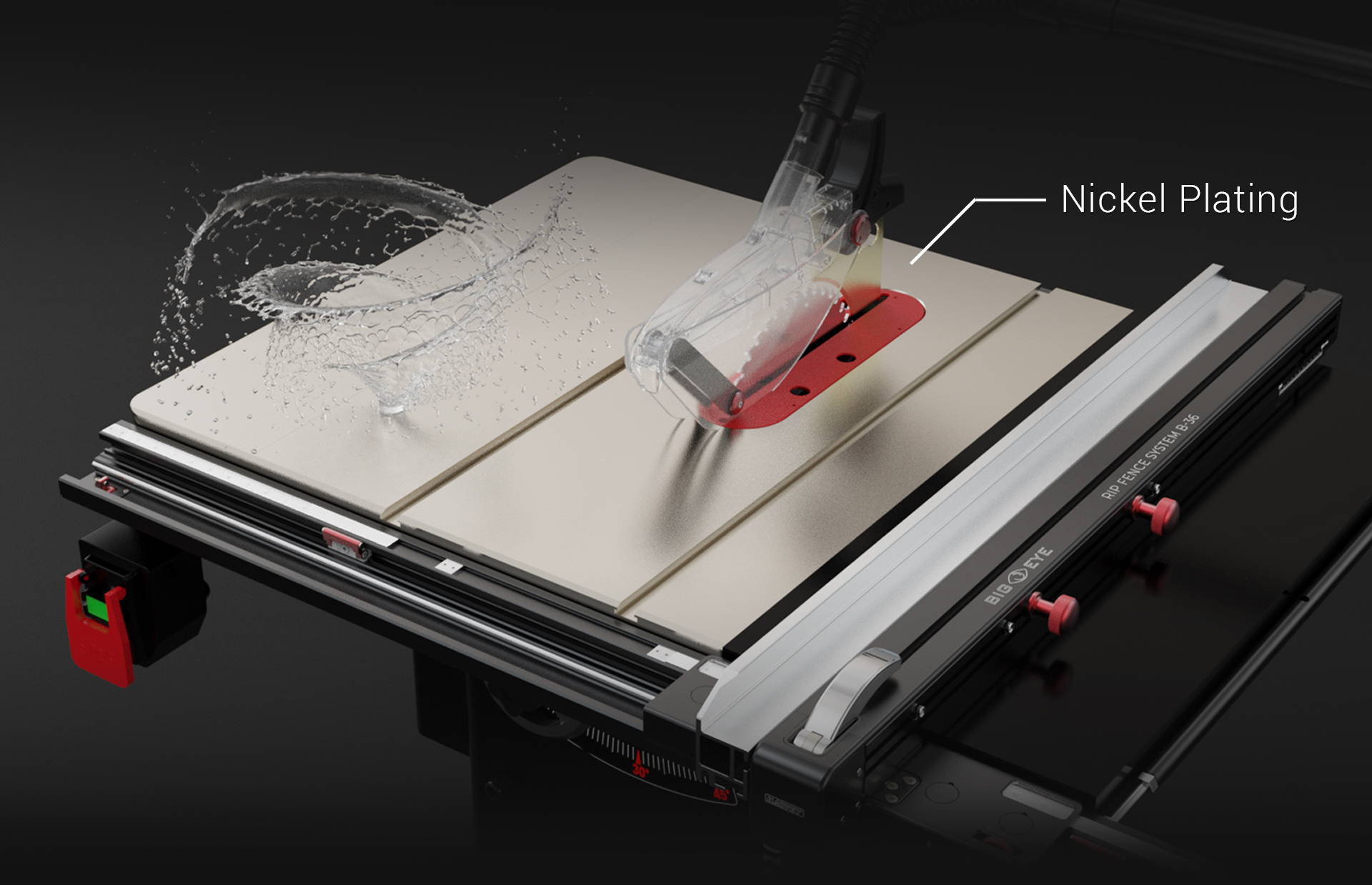

For many woodworkers, rust on table saws has long been a source of frustration. About ten years ago, Harvey began addressing this challenge by incorporating the TiN PVD Coating technology into products, reducing wear and rust on table saw surfaces.

However, Harvey is always striving for perfection. Five years ago, we started exploring the nickel plating technology. After countless tests on the process and formulation, we have successfully implemented optimal nickel plating technology on the tabletop and the Worm Gear Trunnion System within the table saw, ensuring a literally rust-free experience for users by completely eliminating issues of wear and rust.

This superior nickel plating solution adopts the autocatalytic plating process, combining with a mid-phosphorus chemical nickel formula, significantly enhances wear resistance and rust prevention capabilities, resulting in a smoother and more lustrous finish.

Furthermore, the nickel-plated table surfaces achieved an impressive hardness of 500HV - 700HV, considerably improving their wear resistance. Extensive friction tests using wooden blocks consistently demonstrated that the nickel layer effectively protected the table surface.

We conducted a series of high-temperature and strong acid corrosion tests to evaluate the longevity of the nickel-plated surfaces. The results indicated that, under normal usage conditions, the nickel-plated surfaces could maintain their rust prevention performance for years. Notably, even in highly humid working environments, they exhibited exceptional rust prevention capabilities.

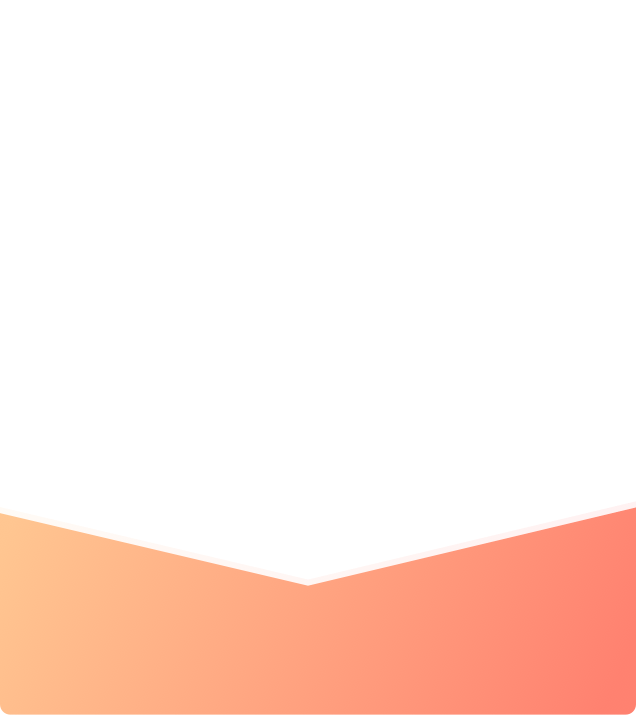

We are confident that the ALPHA HW110LC-36Pro Stain-less Cabinet Table Saw represents the ultimate solution to the rust problem in table saws. Guided by our steadfast philosophy that "Good Enough is Not Enough," these saws exemplify our unwavering dedication to innovation and precision. Central to their groundbreaking functionality is the innovative Big Eye Rip Fence System, revolutionizing woodworking precision and ease of use.

The HW110LC-36Pro series cabinet saws are a testament to performance and safety, incorporating all the exceptional features you have come to appreciate and love in the prior HW110LC-36 series.

Crafted to the highest standards of quality, the ALPHA Series HW110LC-36Pro Stain-less Cabinet Saws are not merely tools but an investment in your craft. Whether you are a seasoned professional or setting up your first woodworking shop, these saws offer the reliability and performance necessary to elevate your woodworking projects to new heights.

Features and Benefits

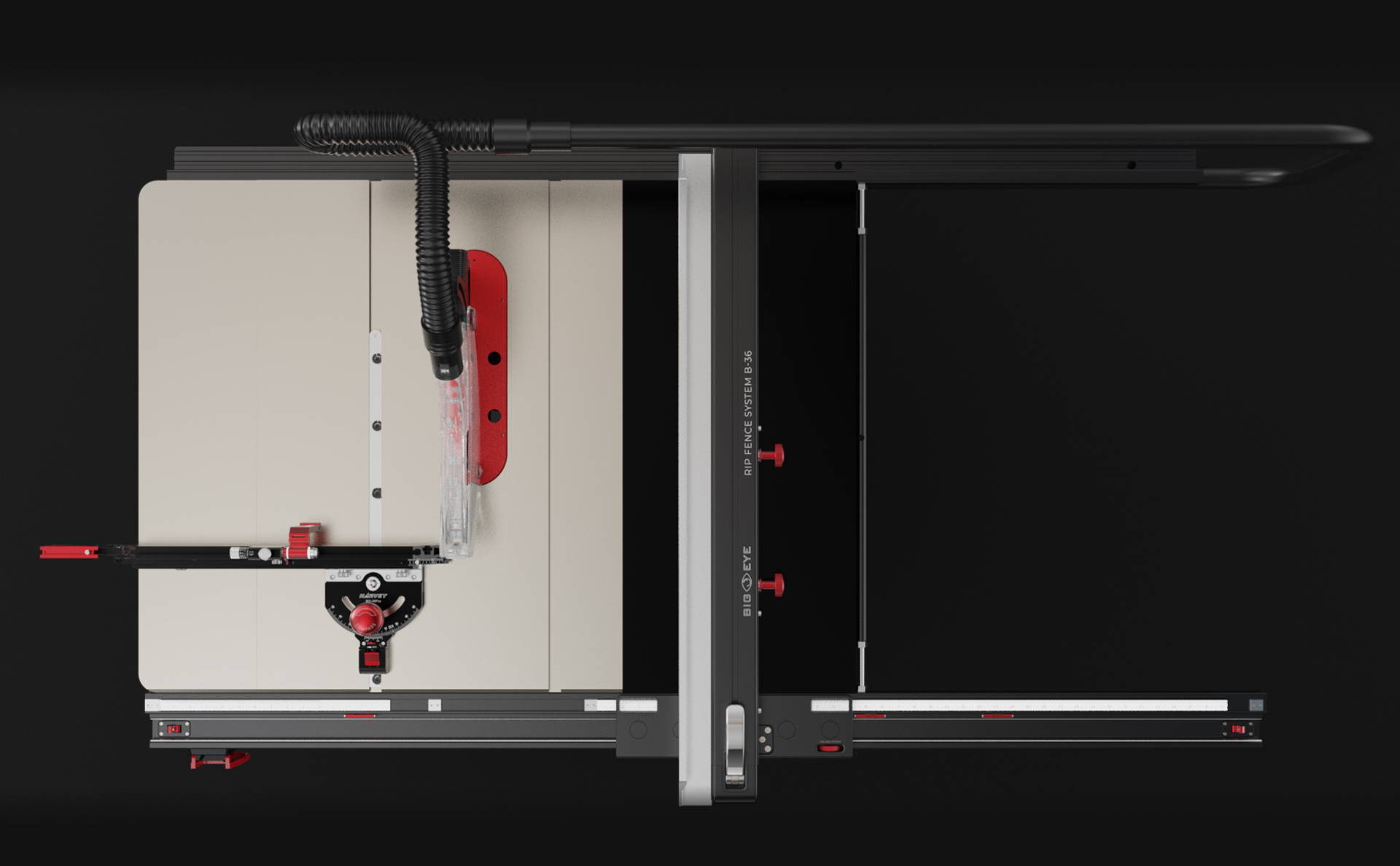

*Unprecedented Big Eye Rip Fence System

*Extraordinary Nickel-plated Cast Iron Table

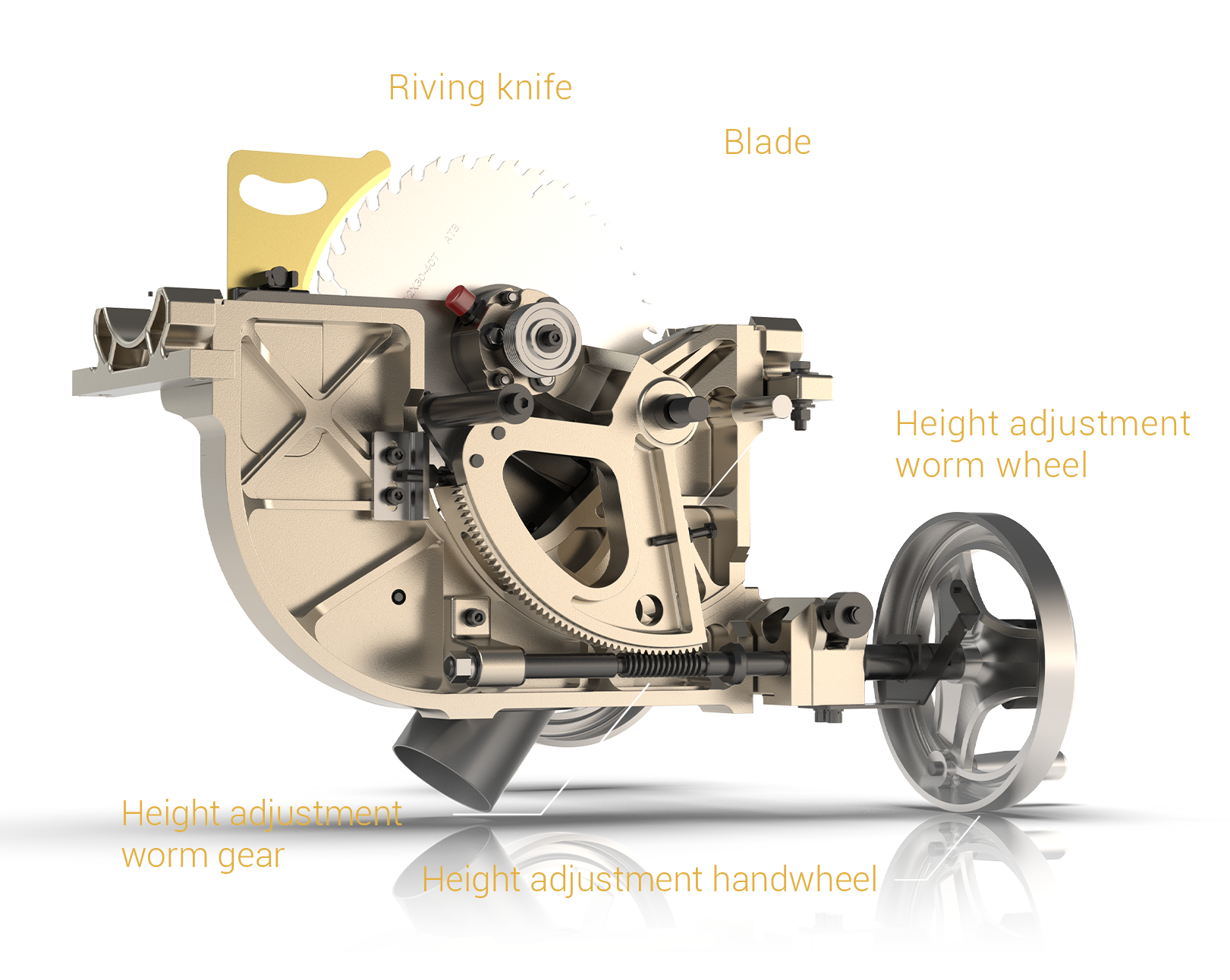

*Unique Nickel-plated Worm Gear Trunnion System

*MG-36Pro "COMPASS" Miter Gauge

*Industrial-grade DESTROYER General Purpose Blade

*The Versatile Fence Positions

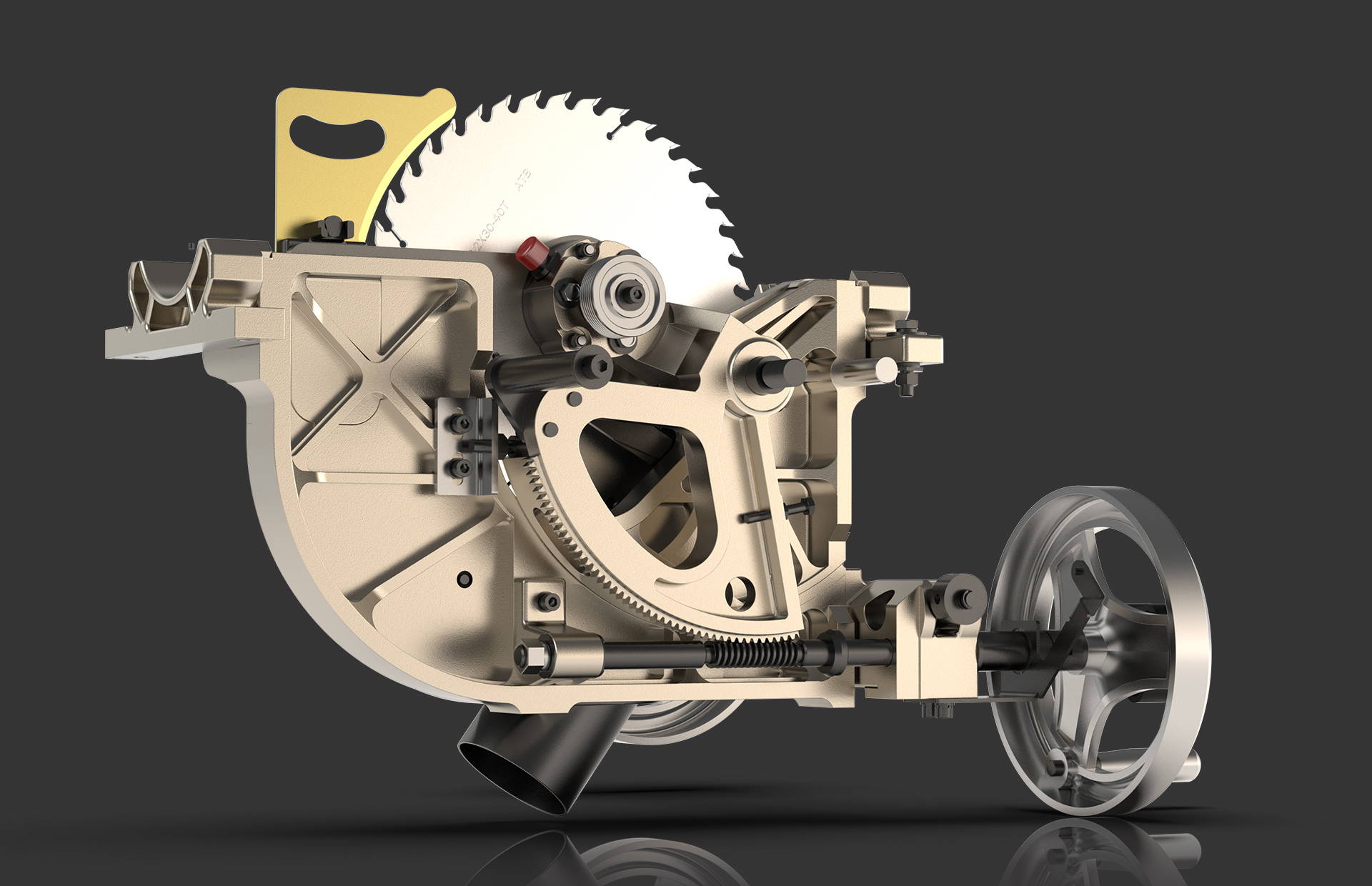

*Special Transparent Blade Guard with Optimized Protection and Dust Control

*Dust Shroud Under Blade

*Built-in Dust Collection Hose System

*Magnetic Safety Switch

Superior Durability and Resistance: The table undergoes a chemical nickel-plating process that bonds the nickel layer thickly to the base material, reaching an impressive hardness range of 500 HV to 700 HV, significantly enhancing its durability and resistance to corrosion and wear. Extensive friction tests using wooden blocks consistently demonstrated that the nickel layer can effectively protected the table surface.

Additionally, we conducted a series of high-temperature and strong acid corrosion tests to evaluate the longevity of the nickel-plated surfaces. The results indicated that, under normal usage conditions, the nickel-plated surfaces could maintain their rust prevention performance for years. Notably, even in highly humid working environments, they exhibited exceptional rust prevention capabilities.

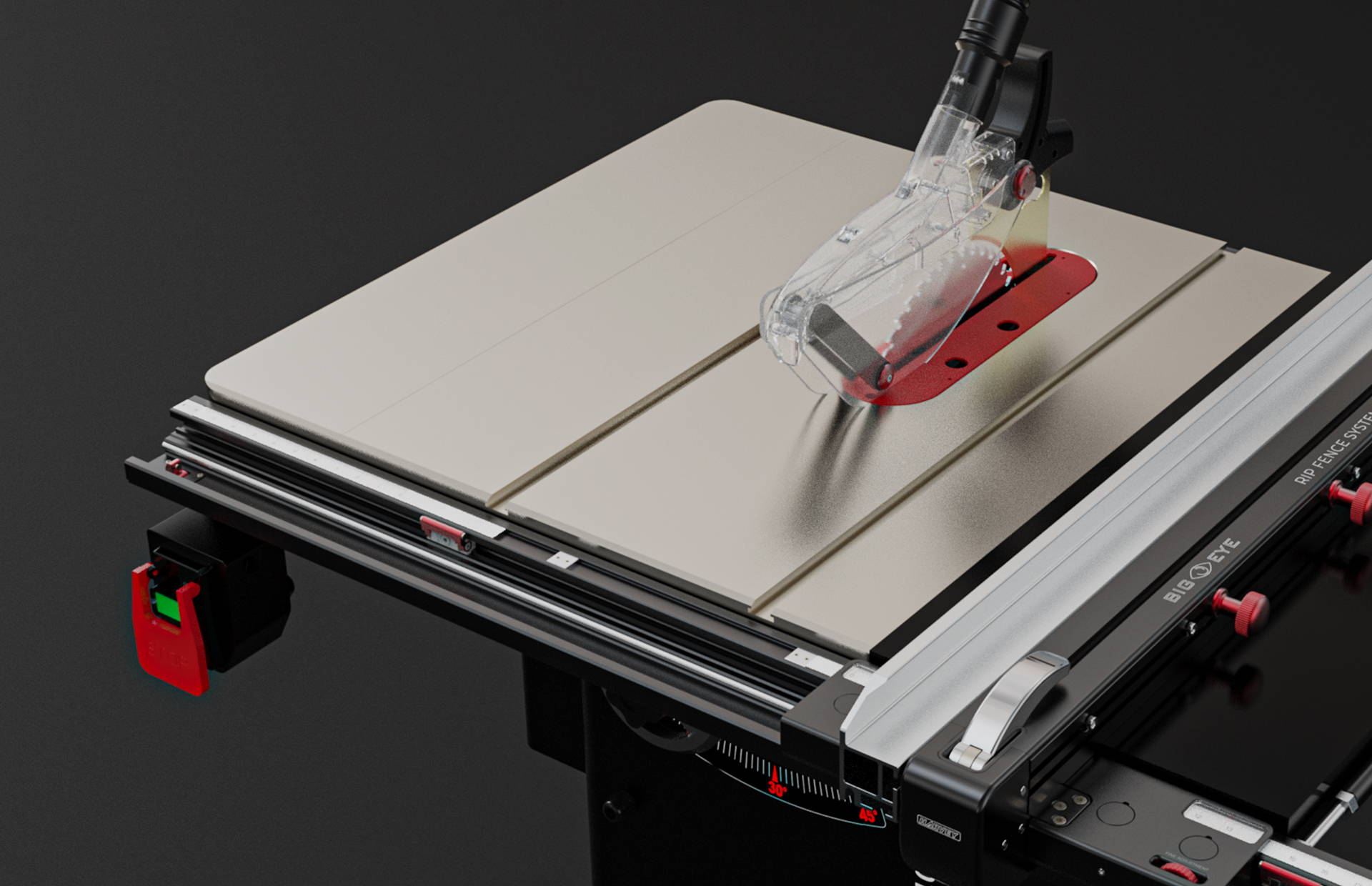

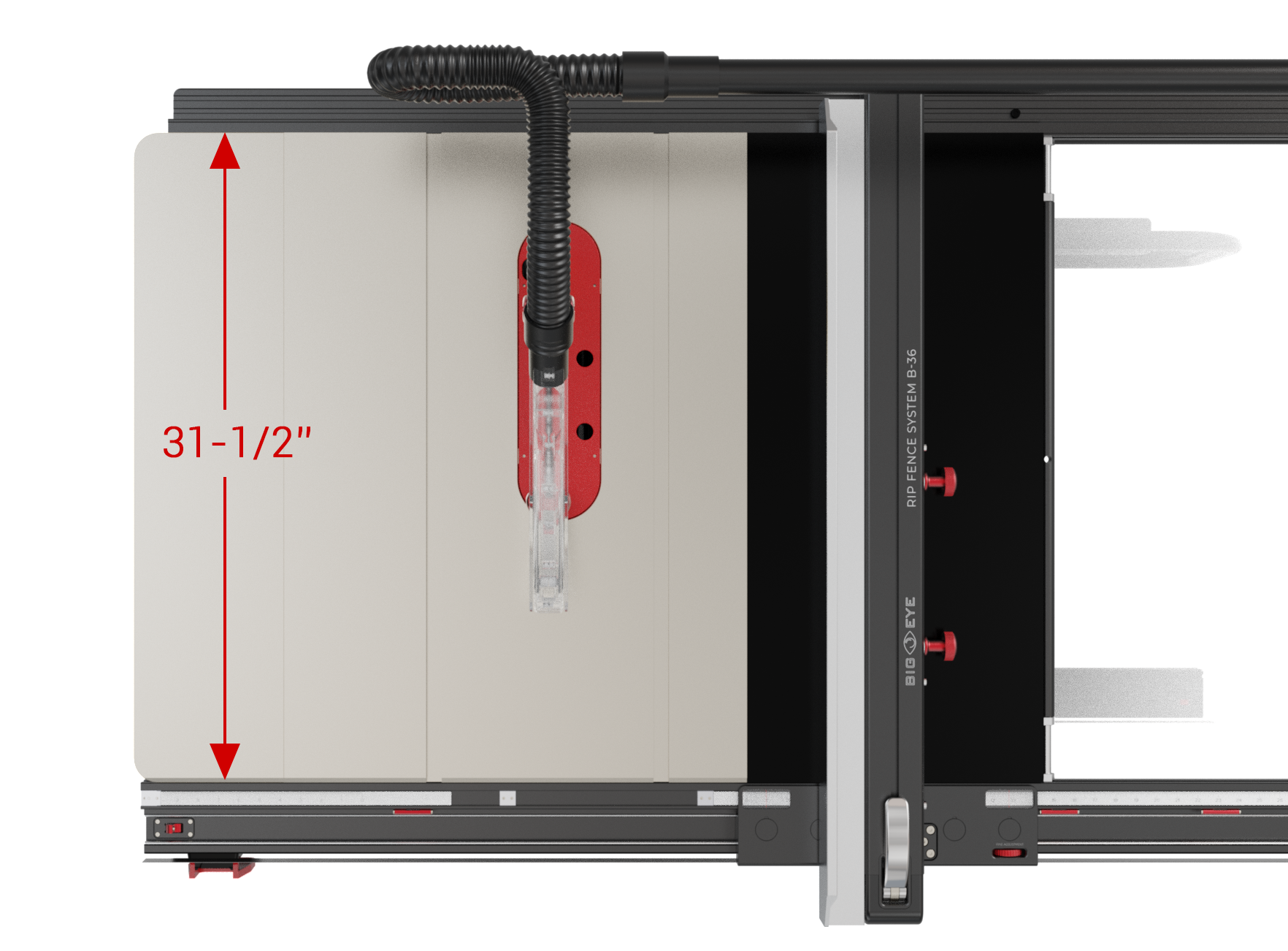

Extended Workspace:

A 31-1/2" deep table surface provides ample space for large pieces, ensuring safe and comfortable operation.

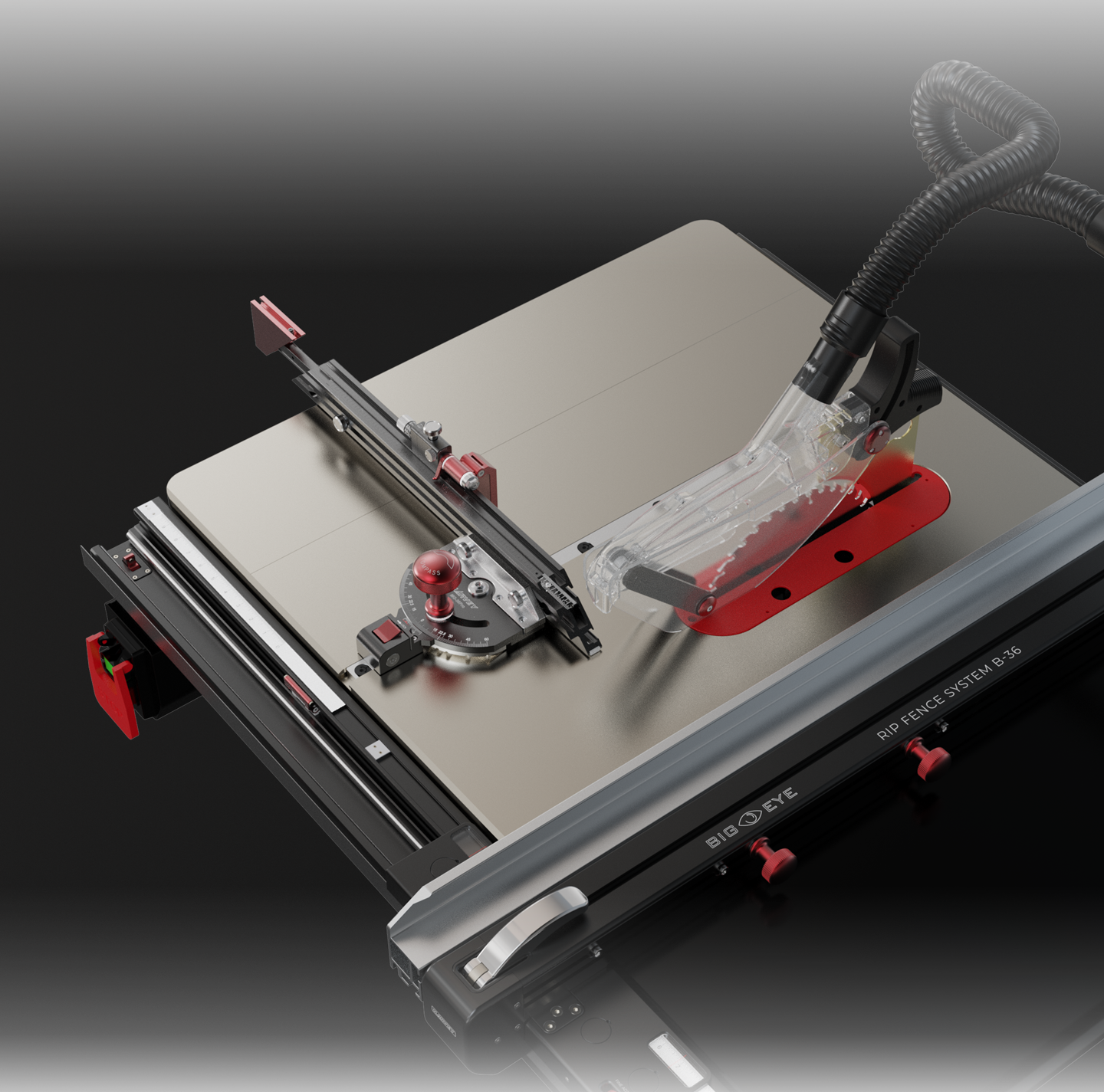

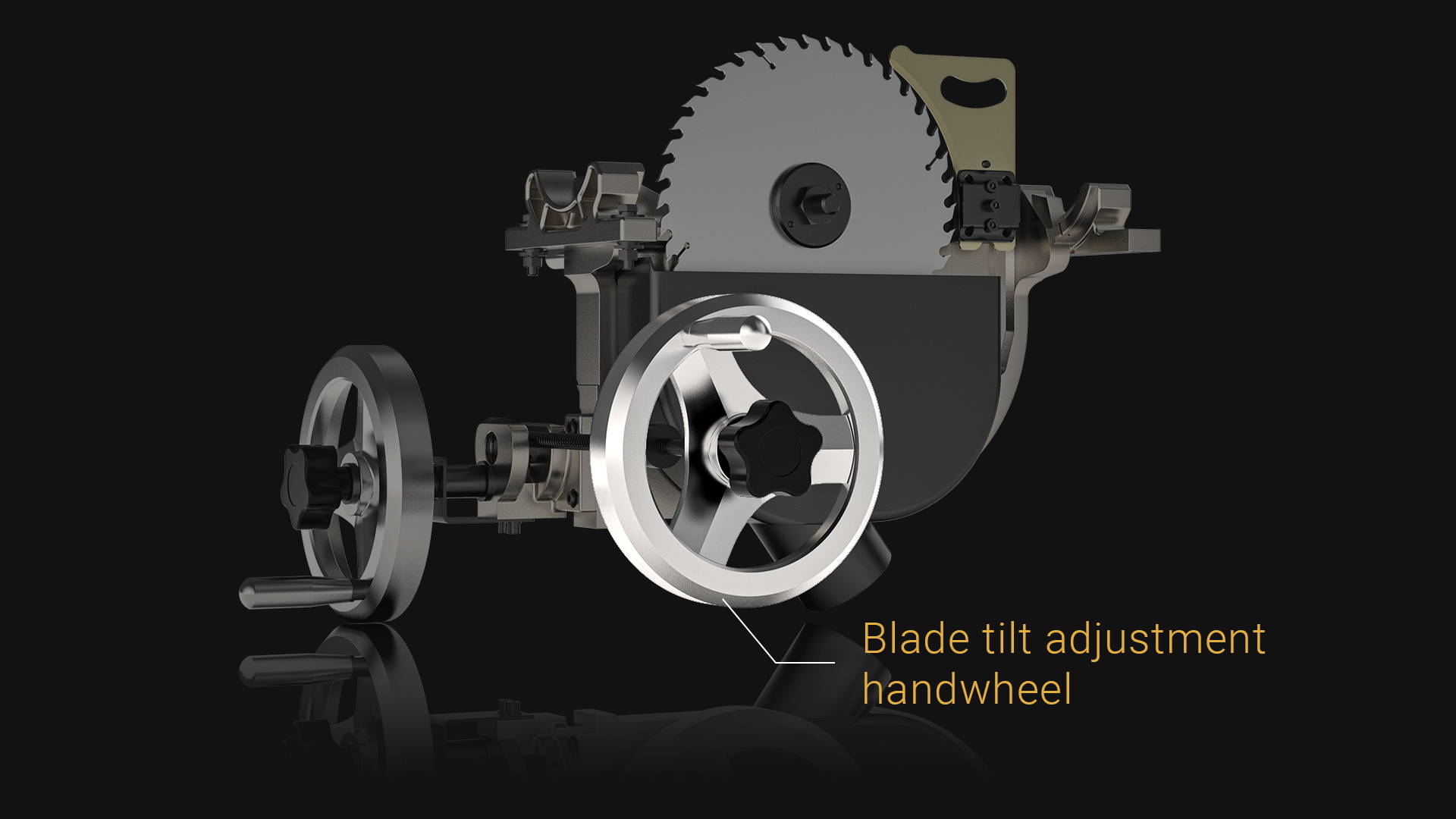

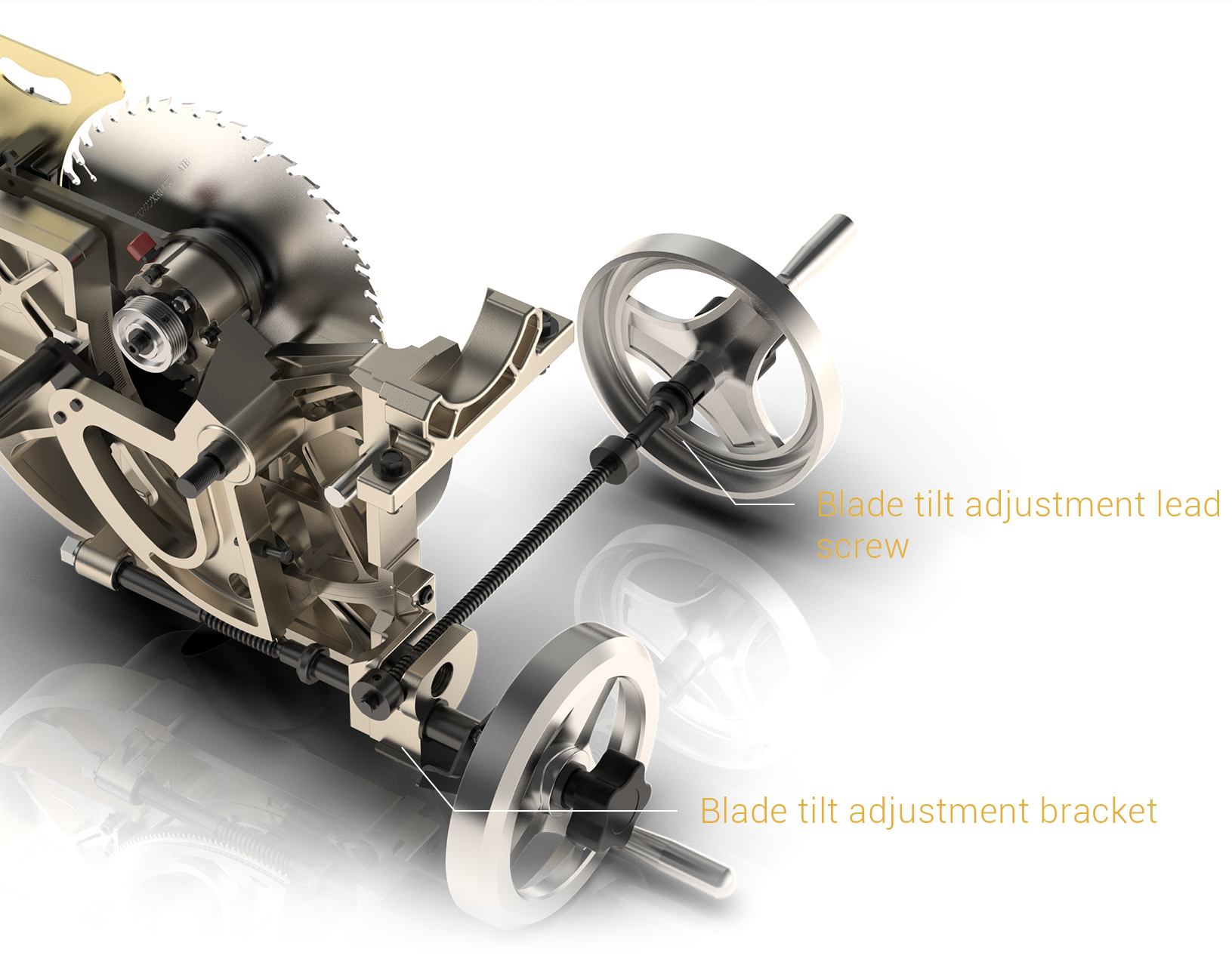

The entire Worm Gear Trunnion System has undergone a nickel-plating process, offering exceptional rust resistance and durability.

The blade elevating and tilting are both controlled by the worm gear trunnion system. The blade is elevated and tilted by swing the worm wheel.

The blade tilting is controlled by the lead screw mechanism. The blade is tilted by the whole blade elevating assembly being moved with a lead screw.

An unprecedented rip-cutting solution for table saws

In order to elevate the user experience and operational efficiency of the HW110S, we've integrated our cutting-edge BIG EYE Rip Fence System into the standard features of the HW110S.

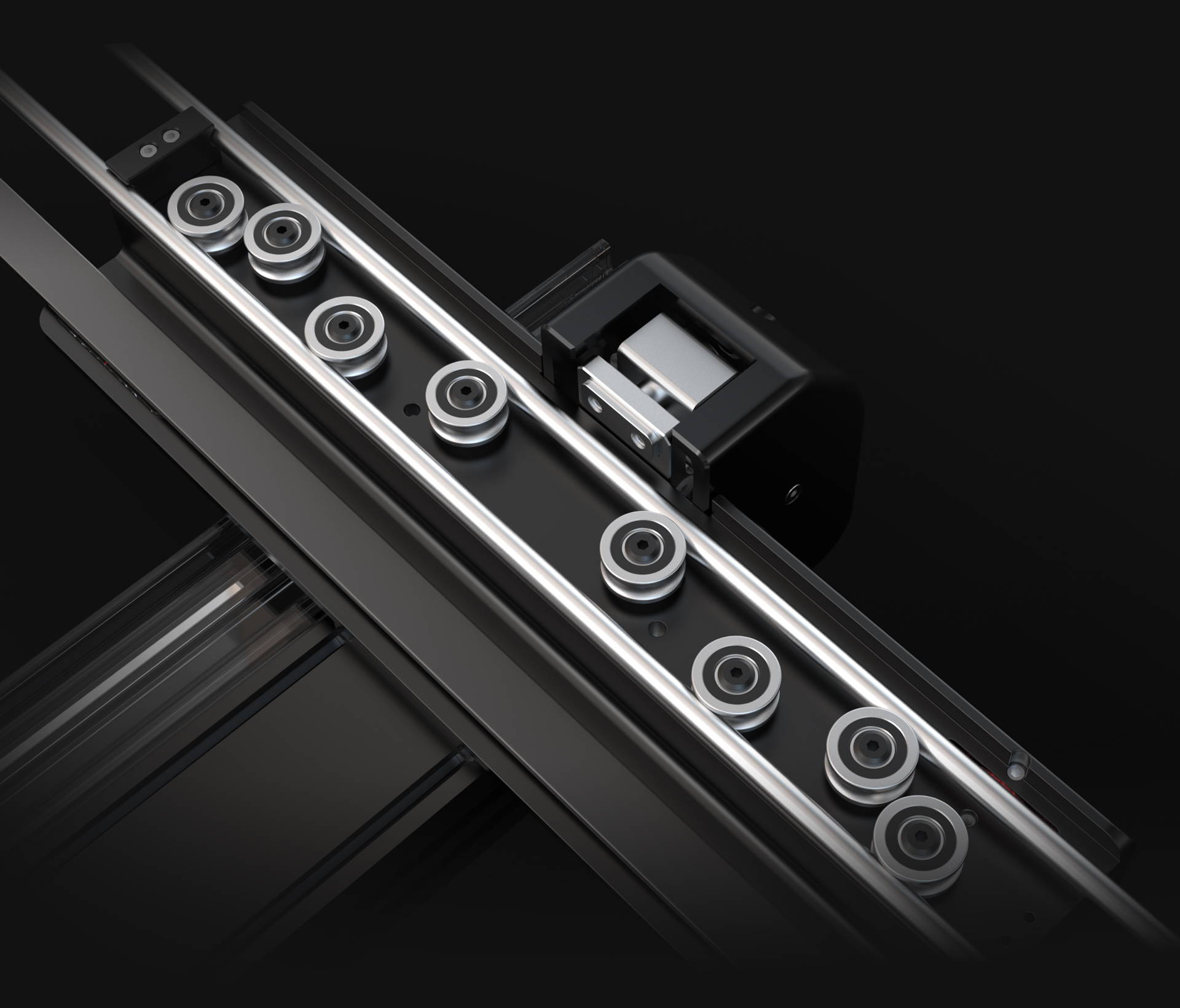

At the core of the Big Eye Rip Fence System lies the Dual-axis Linear Guide Rail System, featuring eight rollers with bearings that effortlessly glide along the two hardened and ground steel rods with zero clearance. This innovative design replaces traditional bushing sliding friction with smooth rolling friction, resulting in exceptional accurate fence movement (0.15mm in full length).

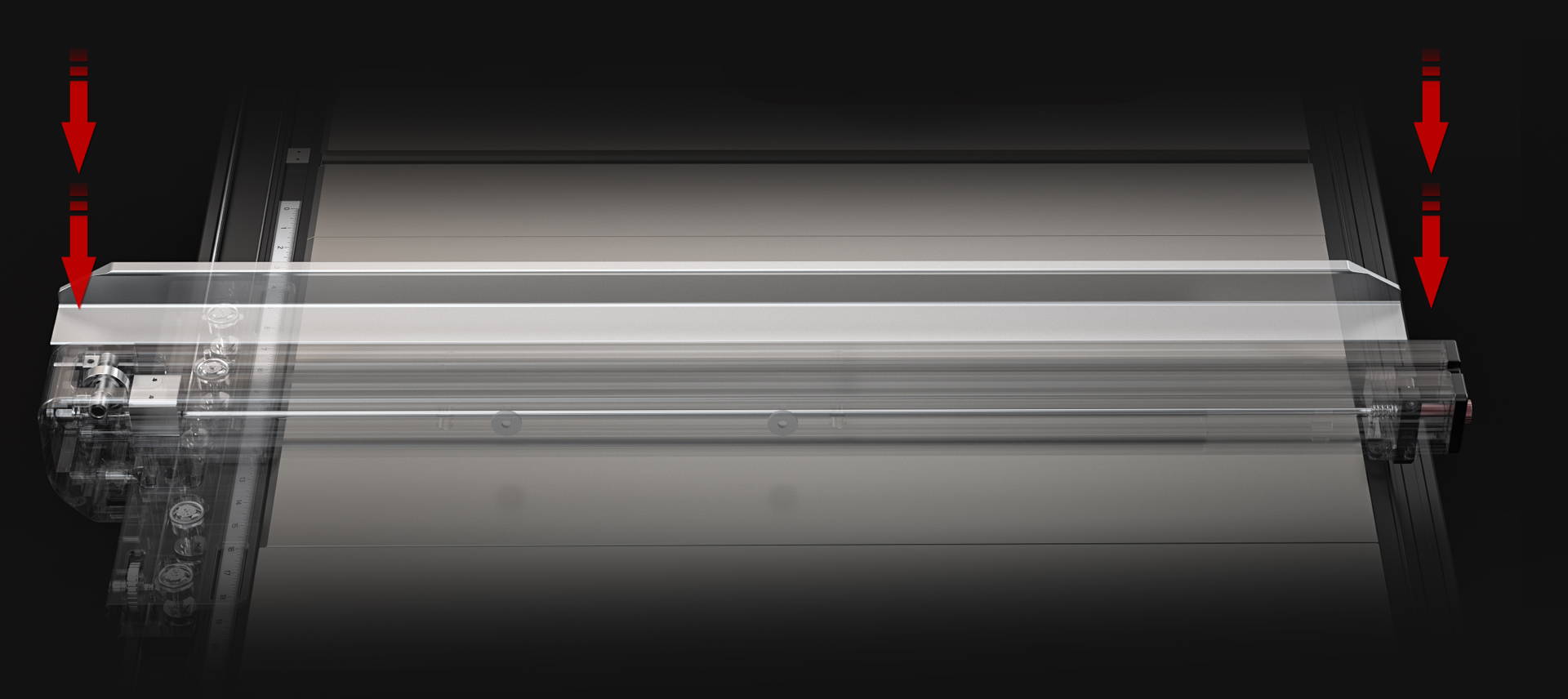

Dual-end Clamping controlled by the linkage mechanism

The innovative Synchronized Dual-end Fence Locking Mechanism enables simultaneous clamping of the fence on to the solid front and rear guide rail bodies, allowing for "Single Action" locking, and preventing the fence from deflective drifts during cutting. With the fence locked in place, the accuracy of the fen